Lines for non filled pasta

Production of non-filled pasta, both fresh and dry

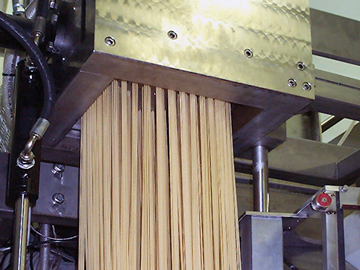

We design and manufacture industrial lines for production of non-stuffed pasta, both dry and fresh.

The dough can be:

- Extruded (spaghetti, fusilli, macaroni, etc.).

- Laminated (tagliatelle, pappardelle, tagliolini, etc.).

- Formed on a conveyor belt (trofie, cavatelli, olive leaves etc.).

The production process consists of the following stages:

Preparation of the dough

Production

There are three pasta production methods:

Treatment

Pasta shelf-life can be increased by means of the following treatments:

Packing

COMBINED PASTA MACHINES

PASTA MIXERS AND EXTRUDERS

PASTA SHEETERS AND CUTTERS

MACHINES FOR FILLED PASTA

GNOCCHI FORMING MACHINES

MACHINES FOR SPECIAL PASTA

AUTOMATIC PASTA COOKERS AND BAIN-MARIE

PASTA COOKING WORKSTATIONS

PASTA BASED FAST FOOD

COOKING LINES AND INDUSTRIAL PLANTS

CONTINUOUS COOKERS

CONTINUOUS PASTEURIZERS

CONTINUOUS COOLERS

CONTINUOUS PRE-DRYERS

STATIC DRYERS

© 2015, 2024 - ITALGI S.r.l. - V.A.T. ID: 01079960991 - C.F.: 01596160182 - R.E.A.: GE - 360111 - Soc. Cap.: Euro 118,000.00 e.v.

Scroll to Top

Italiano (Italy)

Italiano (Italy) English (US)

English (US) Español (Spain)

Español (Spain) Français (France)

Français (France) Deutsch (Germany)

Deutsch (Germany) Português (Portugal)

Português (Portugal) русский (Russia)

русский (Russia)