Lines for filled pasta

Lines for the production and heat treatment in continuous of stuffed pasta

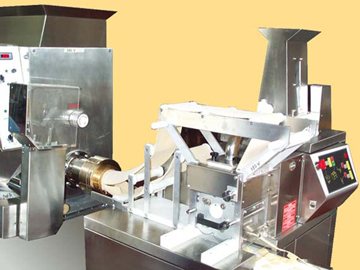

We design and manufacture continuous lines for production and heat treatment of stuffed pasta, both typical Italian (ravioli, cappelletti, cannelloni, etc...) and from other regions of the world ( pierogi, empanadas, pelmeni, etc..).

The lines are extremely efficient; synchronization between the machines allows a considerable reduction of human labor. Both the machines and the lines are designed to minimize time for cleaning and for changing the molds. All electrical and potentially dangerous mechanical components are covered by guards.

To increase the shelf-life of the product, a pasteurizer and other machines for heat treatment can be added at the end of the production line.

Mix preparation and sheet forming

Product forming

The sheet is then automatically conveyed to the forming machines.

Italgi range includes many different solutions for forming stuffed pasta, some of which are listed below:

Heat treatment

Packaging

COMBINED PASTA MACHINES

PASTA MIXERS AND EXTRUDERS

PASTA SHEETERS AND CUTTERS

MACHINES FOR FILLED PASTA

GNOCCHI FORMING MACHINES

MACHINES FOR SPECIAL PASTA

AUTOMATIC PASTA COOKERS AND BAIN-MARIE

PASTA COOKING WORKSTATIONS

PASTA BASED FAST FOOD

COOKING LINES AND INDUSTRIAL PLANTS

CONTINUOUS COOKERS

CONTINUOUS PASTEURIZERS

CONTINUOUS COOLERS

CONTINUOUS PRE-DRYERS

STATIC DRYERS

© 2015, 2024 - ITALGI S.r.l. - V.A.T. ID: 01079960991 - C.F.: 01596160182 - R.E.A.: GE - 360111 - Soc. Cap.: Euro 118,000.00 e.v.

Italiano (Italy)

Italiano (Italy) English (US)

English (US) Español (Spain)

Español (Spain) Français (France)

Français (France) Deutsch (Germany)

Deutsch (Germany) Português (Portugal)

Português (Portugal) русский (Russia)

русский (Russia)